- Machine type:

-

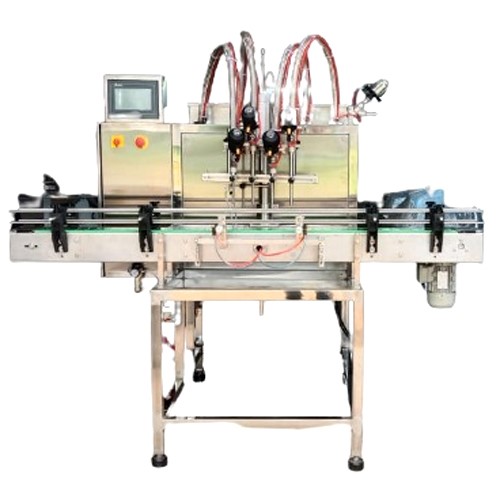

- 1. Rotary piston filling machine

- 2. Volumetric liquid filling machine

- 3. Viscos filling machine

- 4. Semi auto filling machine

| MODEL | 2 HEAD | 4 HEAD | 6 HEAD | 8 HEAD | |

|---|---|---|---|---|---|

| OUTPUT PER HOUR | 700 TO 2000 | 2200 TO 6000 | 3300 TO 9000 | 4400 TO 12000 | |

| FILL SIZE | 5 ML TO 1000 ML | 5 ML TO 1000 ML | 5 ML TO 1000 ML | 5 ML TO 1000 ML | |

| ELECTRIC SPECIFICATION | 2 HP/415 VOLTS/50 HZ. | 2 HP/415 VOLTS/50HZ | 2 HP/415VOLTS/50HZ | 2 HP/415VOLTS/50HP | |

| CONVEYOR HIGHT | 850 MM TO 900 MM ADJUSTABLE | ||||

| MACHINE DIMENSIONS | 2100mm x 1300mmx 1700mm | ||||

| *WEIGHT | 550 KG | 600 KG | 700 KG | 800 KG | |

| MAINTANACE | NOZZLE ,HOSE PIPE, VALVE AND O RING | ||||

Description of Automatic Rotary Piston Machine:

“RPMS”s Automatic Rotary Piston Filling Cum Sealing Machine is versatile, self-supported on stainless steel leg with height adjustable adjustment system. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are providing to facilitate the servicing of machine, work on volumetric principle with rotary motion. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body. No container No filling & No Sealing system arrangement is standard features of the machine.The main drive of the machine, conveyor drive & cap-feeding bowl consist of A/c Motor with synchronized variable A/c Frequency Drive.

Operation:

Containers moving on SS Slat conveyor, feed below the filling nozzles through feed worm & in-let star wheel, Filling station consist of volumetric filling head and a central rotating liquid reservoir tank. This reservoir tank fed continuously with the liquid by external source. In-feed liquid controlled automatically by sensing the liquid level in the reservoir tank with the help of float switch to actuate pneumatically operated solenoid valve. Fill volume adjustment can be done by a screw, which changes the volume of all the syringes simultaneously. Fine adjustment of individual syringe is possible with the help of mechanism provided on top of the individual syringe.

After filling star wheel bringing the container below the sealing head in the subsequent indexing part, meanwhile the bottle pick up a cap from the delivery chute of cap filling bowl, where the body and the neck of the container are positioned below the rotating head, where the sealing head is performing perfect operation of threading & sealing.

Description Of Automatic Volumetric Machine:

“RPMS”s Automatic Volumetric Liquid Bottle Filling Machine work on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Reciprocating Nozzle with self-cantering devices & SS Syringe. No container No filling system arrangement is standard features of the machine.

The main drive of the machine, conveyor drive & cap-feeding bowl consist of A/c Motor with synchronized variable A/c Frequency Drive.

Description Of Automatic Viscos filling Machine:

“RPMS”s Automatic Viscos Liquid Bottle Filling Machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine. Machine works on volume=time technology and speed=flow rate. The unit is made compact, versatile and S.S. body. “No container-No filling” system arrangement is standard features of the machine. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body. Frequency Drive.Description Semi-Automatic Filling Machine:

“RPMS”s Semi-Automatic Volumetric Liquid Filling Machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine. Working on volumetric principle. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body.